mark 3

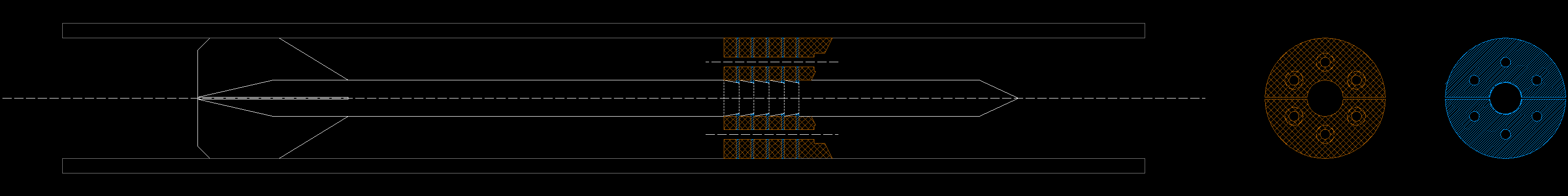

This is a relatively portable aircannon meant

to be carried by a person. It features a 3' x 4" chamber, and a 5' x 2"

barrel. The piston valve is an improved design that fills more quickly and

seals better than the one in the Mark 2. The size and shape allow it to be

easily carried, thus eliminating the setup necessary to position and aim the

earlier cannons.

A new projectile was developed for this cannon, based on

modern anti-tank rounds.

Stainless steel guide rods from scanners and printers

are sharpened to a point, then fitted with fins. A steel disk is placed at

the end as a pusher, and pieces of foam cut from a pool noodle are used to

keep the rod centered. An improved sabot is being designed, based on the

spindle sabots used on actual anti-armor rounds.

![cannon]() |

The Mark 3. The design is simple. The parts are all fairly obvious

and the valve assembly is almost identical to that of the Mark 2. |

|

We decided a 5' long barrel was not long enough, so this was our solution: a 10' segment

of 2" PVC to be coupled on to the end with that rubber coupler. Calculations

indicate that this should provide two to 2.5 times the output energy. The coupler is

soft, which makes alignment problematic. This will eventually be fixed with some bracing

or a mount. |

|

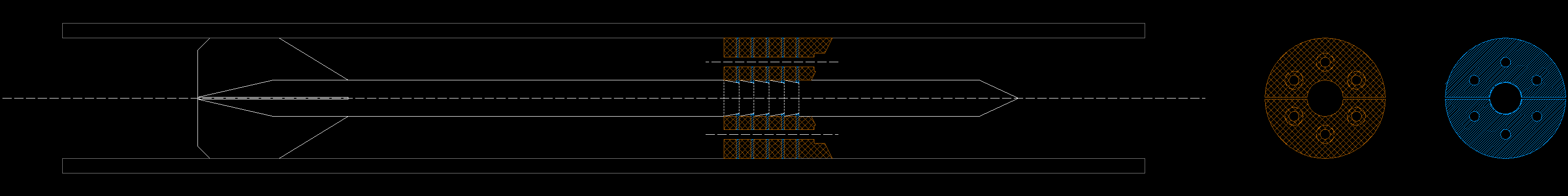

A CAD drawing of how the new sabot will go together, and what each layer looks

like. It is made of thin metal disks separated by plastic disks, all bolted together.

The metal disks have a smaller inside diameter and thus grab onto the barbs on the

projectile. |

|

A couple of rods we shot through various things. The bent one ended up that

way after travelling through a hard drive, a CD-ROM drive, a computer, and a book,

finally hitting a tree while spinning and deforming the rod. It has grooves cut into the tip

such that it resembles a Phillips screwdriver. The bottom one has no such grooves and

we suspect penetration is decreased because of it. |

|

This is a hard drive shot with a rod using the '+1' barrel extension. Priority Mail

stickers were used as tape to hold the drive to the target stand. |

|

Disassembling the hard drive reveals that the rod went through the front cover,

two platters, the back cover, and the circuit board. Note the four-pronged burr on the hole

in the front cover, suggesting that the four grooves cut into the tip of the projectile

performed as expected and produced a sort of cutting action on the plate. |

|

This is another hard drive, shot twice with the same projectile. This drive was somewhat tougher

than the previous one, with a steel front cover and three platters instead of two. The first shot

struck approximately the same place as the shot on the previous drive, again penetrating the entire

drive. The second shot struck the voice coil magnet, shattering it and tearing apart the magnet's

backing plates, and breaking the entire drive casing in two. |

|

Here is a closeup showing damage to the platters and other internal components. |

|

A computer case after being the recipient of several rods. This was the backstop against which our

targets were placed. |