sound-tron: experimental whistle

This unusual whistle was inspired by the cavity magnetron, the device in every microwave oven that generates microwaves. Inside the cylindrical core of a magnetron is a heated cathode along the axis that emits electrons, and an axial magnetic field that causes the electrons to swirl around in a central cavity. Surrounding this cavity are a number of resonant cavities that are energized by the swirling electrons, generating a rapidly-alternating electric field whose frequency is governed by the size of the cavities.

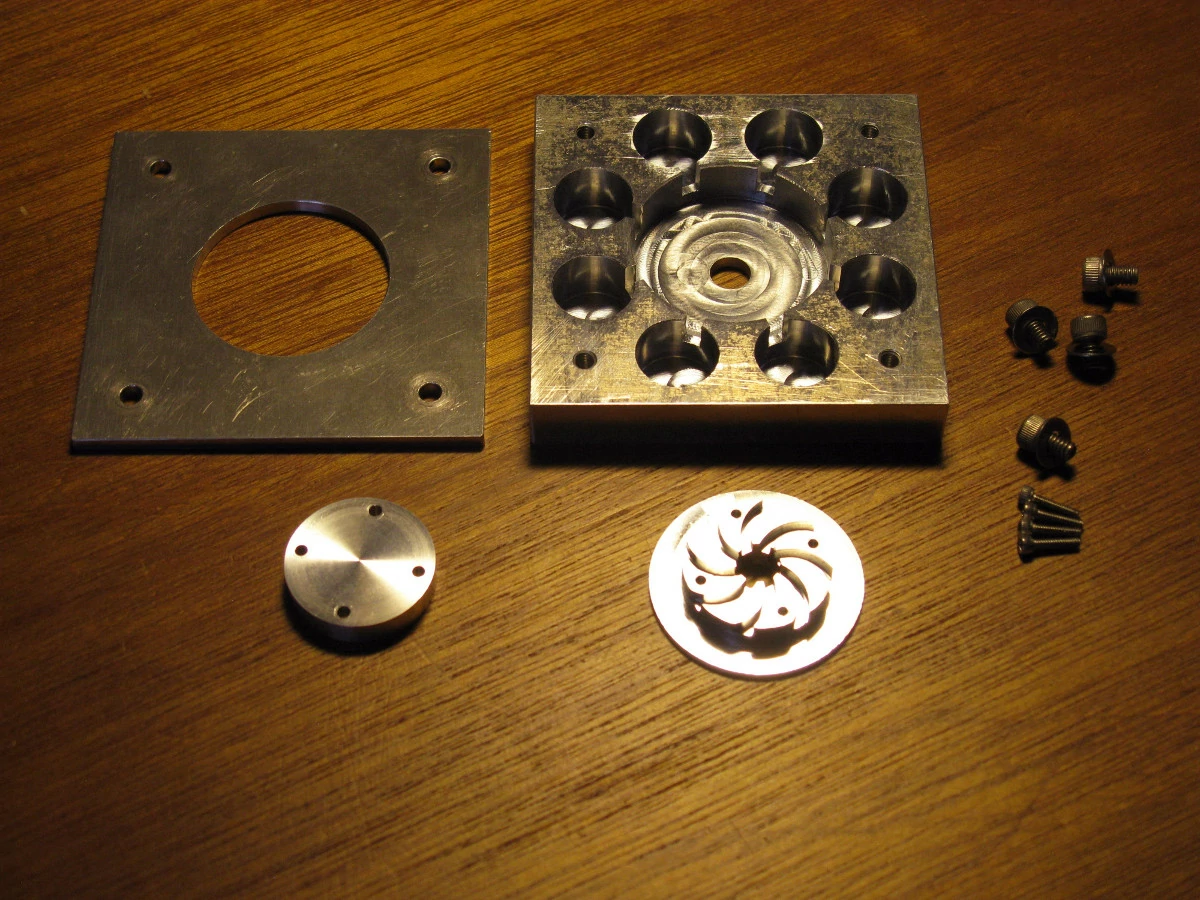

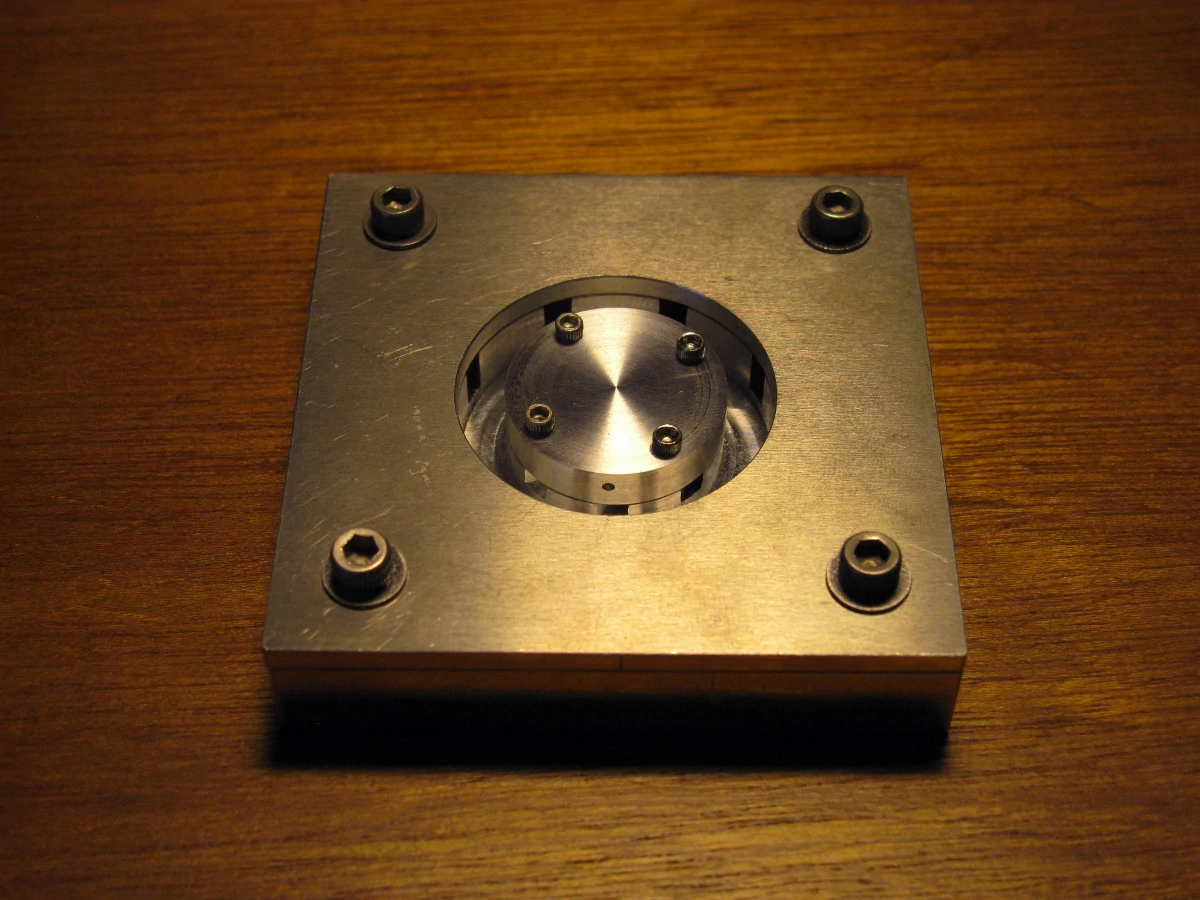

Again with the help of Ray and his shop, I produced a rough air-driven analogue to the magnetron. Inside, there are eight resonant cavities surrounding a central cavity, where a stator directs incoming air to swirl around it. As the air passes over the opening to each cavity it causes the cavity to resonate, akin to blowing over the top of a bottle. Sound is emitted from the ring-shaped opening.

As is, the whistle is rather temperamental and especially sensitive to the angle of the stator. It also requires a great deal of airflow and is best used with a blowgun fed from an air compressor or similar.